Image 1 of 8

Image 1 of 8

Image 2 of 8

Image 2 of 8

Image 3 of 8

Image 3 of 8

Image 4 of 8

Image 4 of 8

Image 5 of 8

Image 5 of 8

Image 6 of 8

Image 6 of 8

Image 7 of 8

Image 7 of 8

Image 8 of 8

Image 8 of 8

Five Day Knife Making Experience

This is a five day knife making experience week where you will learn to take sheet steel and transform it into a high quality tool that you can take home with you. the process is known as stock removal and is a more consistent technique of making knives to stand the test of time!.

The week will start with a nice chilled walk through of the workshop and a rundown on all the gear we’ll be using. We will then move on to choosing the design of knife you’d like to make as well as discussing design pros and cons to aid you in future knife designing. You will have the option to choose from any of our knife designs or should you wish we can sit down and design your very own unique design.

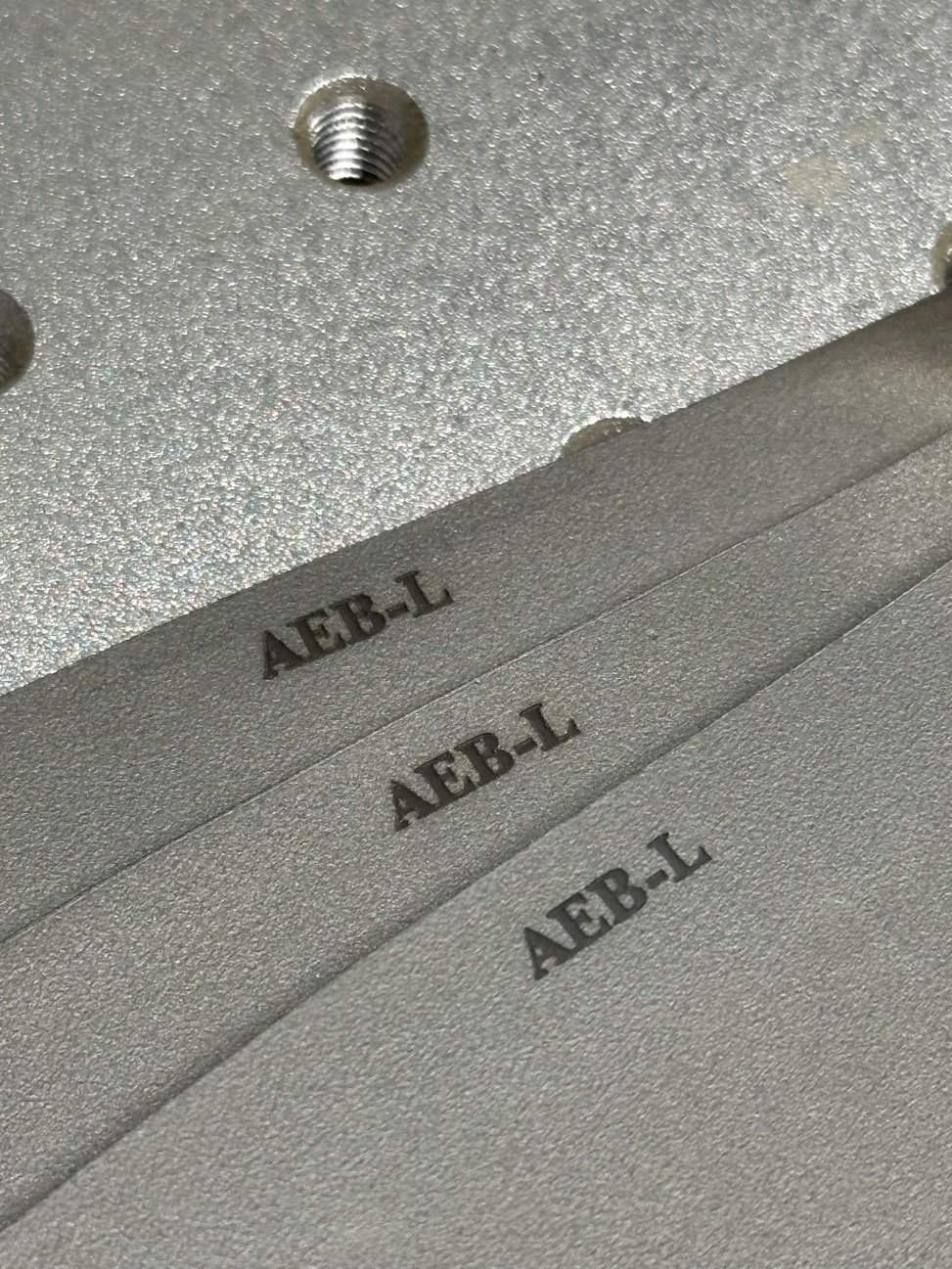

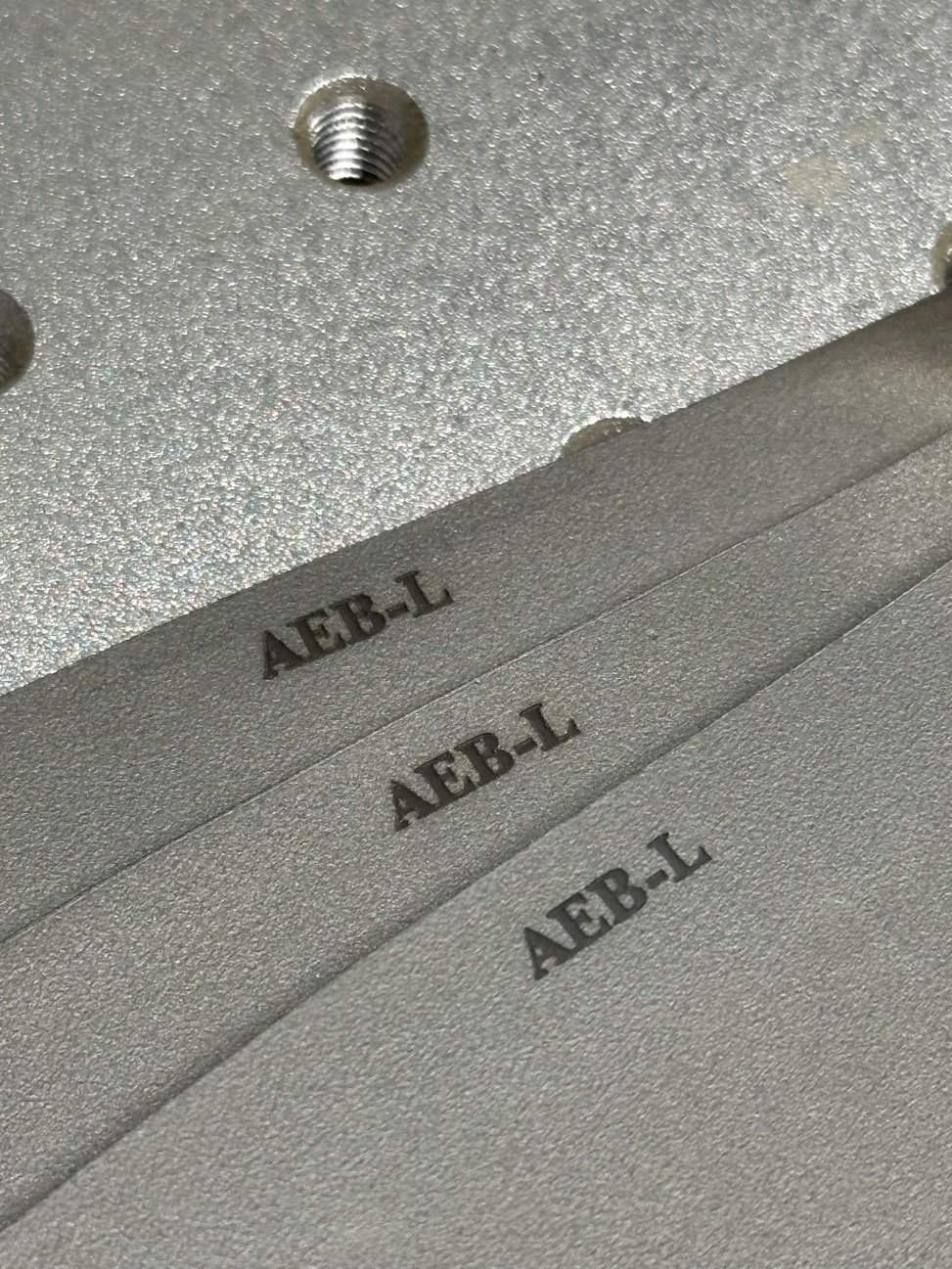

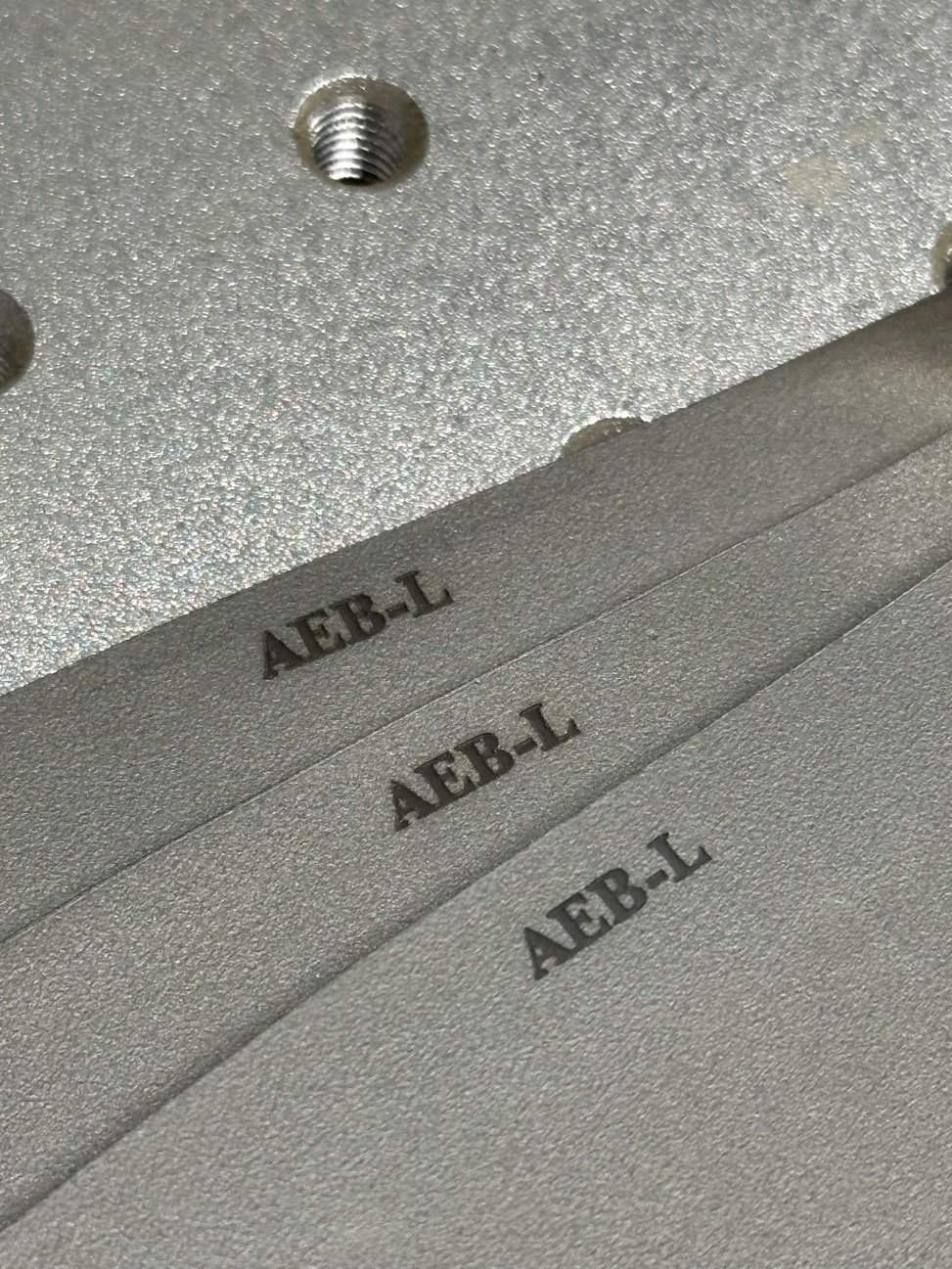

Throughout the week you will then be guided through the entire process, starting with cutting out the blade from sheet steel, rough grinding the blank and bevels, Layout/drilling for bolt/lanyard holes, adding jimping if desired, heat treating the blade which will include a detailed explanation of the science behind heat treating both stainless steels and carbon steels (as well as cryogenic treatment of stainless steels), next will be post heat treat bevel grinding and blade finishing to include a section on blade geometry and how the combination of geometry and the heat treating process will make or break the end product, moving on to engraving via fibre laser be it logo/steel type/custom engravings, next handle scale preparation, handle glue up, rough handle shaping, handle finishing and sharpening. At that point your knife will be complete and we’ll move onto making a quality leather sheath to keep both your knife and you safe!

The processes above cannot be rushed and do involve a fair amount of waiting time between certain steps in the process. However you will be far from idle in those times as you will be set tasks practicing the various steps between working on your own knife, this way you will go away at the end of the week with a lot more experience than just a standard knife making course. Repetition is key to learn these skills.

Age: Over 16y/o only

Clothing: Please wear cotton clothing that you don’t mind getting dirty and potentially damaged.

Food: Not included

Board: Not included

Location: Station Road Industrial Estate, Station Road, Woodchester, Stroud, GL5 5EQ

This is a five day knife making experience week where you will learn to take sheet steel and transform it into a high quality tool that you can take home with you. the process is known as stock removal and is a more consistent technique of making knives to stand the test of time!.

The week will start with a nice chilled walk through of the workshop and a rundown on all the gear we’ll be using. We will then move on to choosing the design of knife you’d like to make as well as discussing design pros and cons to aid you in future knife designing. You will have the option to choose from any of our knife designs or should you wish we can sit down and design your very own unique design.

Throughout the week you will then be guided through the entire process, starting with cutting out the blade from sheet steel, rough grinding the blank and bevels, Layout/drilling for bolt/lanyard holes, adding jimping if desired, heat treating the blade which will include a detailed explanation of the science behind heat treating both stainless steels and carbon steels (as well as cryogenic treatment of stainless steels), next will be post heat treat bevel grinding and blade finishing to include a section on blade geometry and how the combination of geometry and the heat treating process will make or break the end product, moving on to engraving via fibre laser be it logo/steel type/custom engravings, next handle scale preparation, handle glue up, rough handle shaping, handle finishing and sharpening. At that point your knife will be complete and we’ll move onto making a quality leather sheath to keep both your knife and you safe!

The processes above cannot be rushed and do involve a fair amount of waiting time between certain steps in the process. However you will be far from idle in those times as you will be set tasks practicing the various steps between working on your own knife, this way you will go away at the end of the week with a lot more experience than just a standard knife making course. Repetition is key to learn these skills.

Age: Over 16y/o only

Clothing: Please wear cotton clothing that you don’t mind getting dirty and potentially damaged.

Food: Not included

Board: Not included

Location: Station Road Industrial Estate, Station Road, Woodchester, Stroud, GL5 5EQ